Officially presented at Glasstec 2008, Chromatech Ultra is the most remarkable technological innovation to sweep the warm edge spacer sector. It all stems from the need to develop IG performance levels and expand the application possibilities of warm edge technology, which is more and more in demand due to the increasing focus on energy savings.

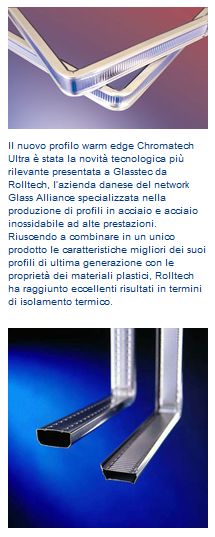

With the primary aim of reducing thermal exchange between interior and exterior, while at the same time obtaining the utmost ease of processing, Rolltech managed to combine the best features of its latest generation stainless steel profiles -- the well-known and widely acclaimed Chromatech Plus -- with a new technology developed by drawing on the use of plastics. The solution devised for the new Chromatech Ultra spacer calls for the use of a dual structure – a lower one made of stainless steel, following the parameters already widely proven with success; the upper one made of polycarbonate, with a particularly low heat transfer index. The end result is a product that manages to ensure many noteworthy benefits in terms of thermal insulation.

It’s well known that most of the energy consumed in homes is used to maintain the ideal interior temperature, through heating in the winter and cooling in the summer. But it is also known that 40% of the energy used to accomplish the objective is lost through windows and doors, which are usually inefficient and inadequate. Chromatech Ultra makes a major contribution toward improving the efficiency and thus, the energy performance levels, of buildings. In fact, it manages to obtain a reduction in the Uw thermal transmittance value up to 0.2 W/sq. m K, increasing the energy efficiency of the home. These results are made possible by the low linear thermal bridge guaranteed by the new profile. Its lower thermal conductance corresponds to lower thermal transmittance within the I.G. unit. With any kind of window, in double or triple glazed systems, the use of Chromatech Ultra makes it possible to cut the ѱ factor in half, in other words, the linear thermal transmittance coefficient around the perimeter of the insulating glass. In regard to this, the comparison is very significant – with aluminum windows, using traditional spacers, you have a ѱ value of 0.111 W/mK; whereas, with Chromatech Ultra the ѱ value drops to 0.051 W/mK, but can also go as low as 0.045 W/mK using triple glazing.

This exceptional performance means added value for glass processors, in consideration of the great ease of use – it is not necessary to use costly machines for perfect bending with sturdy corners and excellent quality. In fact, the profile bends perfectly with the bending machines normally used for aluminum profiles.