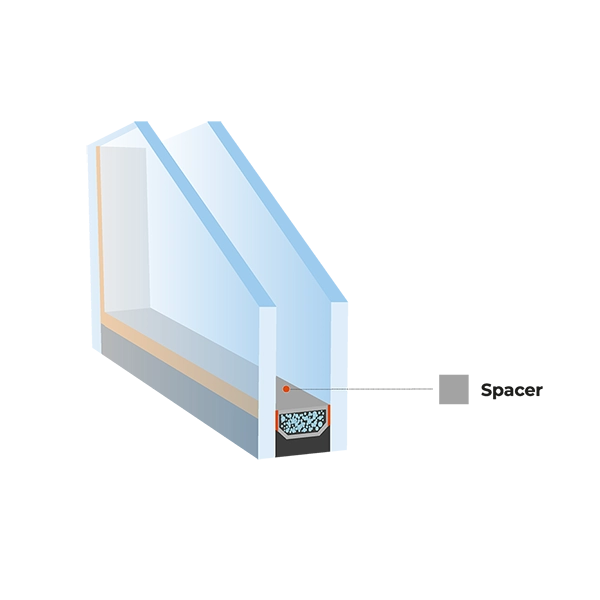

Spacers

Spacer bars are essential components in the manufacturing of insulation glass units. These bars are typically made from materials like aluminum, stainless steel, or plastic, and are filled with desiccants such as molecular sieves to absorb moisture and prevent condensation within the IGU. High-quality spacer bars are crucial for achieving the desired thermal insulation properties.

Warm edge spacers are advanced spacers designed to improve the thermal efficiency of the unit. Unlike conventional aluminum spacers, warm edge spacers are made from materials with lower thermal conductivity, such as thermoplastics, or composite materials. This design minimizes heat transfer at the edges of the glass, improving the overall insulation performance of the IGU. Warm edge spacers contribute to better energy efficiency, lower heating and cooling costs, and enhanced comfort in buildings.

Fenzi Group supplies IG unit manufacturers with the most extensive range of conventional aluminum, warm-edge and hybrid spacer bars.

Choose your product category

Aluminum and Steel spacers

Super Low Thermal Conductivity Polymers

Double Spacer cover strips

Products menu

Tel +39 02 906221

Copyright © 2026, FENZI S.p.A. Tutti i diritti riservati - P.Iva 11328880155